|

Although regarded as a

"black art" air conditioning isn't, so this is a layman's guide

for BFF members (and others) who have troubles with their air-con and

want to check as much as they can before calling in that man with the

gauges.

As a friend who started

out doing air-con with me once said, "Well it isn't quite Rocket

science is it!" Its not that complicated so I hope that some of you

will benefit from the words and pictures that I hope will give you a basic

insight into it and possibly help you along as well but just remember

that this is a simple guide, there is a lot more to it as I regularly

find out!

In its basic form as we

see it on Ag equipment it is quite simple when laid out in layman's terms,

which is the aim of this help page. Although problems may arise when you

throw in climate control and engine management found in some of today's

top end applications the basic principles are the same.

WARNING, DO NOT

DISCONNECT ANY FITTINGS OR PIPEWORK WITHOUT FIRST CHECKING THAT THERE

IS NO GAS IN THE SYSTEM WITH A SET OF TEST GAUGES.

REFRIDGERATION GAS WILL

GIVE YOU SEVERE FREEZE BURNS AT BEST.

The Basics.

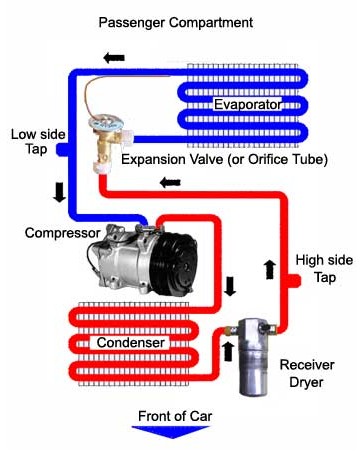

This

is a simple Air-con system. One pump, two radiators, a controlling valve

and a filter/dryer/tank in one. That's all there is in a basic set up. This

is a simple Air-con system. One pump, two radiators, a controlling valve

and a filter/dryer/tank in one. That's all there is in a basic set up.

The compressor(pump)

sucks GAS in from the blue pipe and compresses it from LOW pressure into

HIGH pressure because the red pipe into which it is pumped has a restriction

(either an Expansion valve or an Orifice tube).

A byproduct of this

is that it becomes extremely hot so it first passes through the CONDENSOR

which is cooled by the engine fan, this cools & condenses the gas

into a HIGH PRESSURE LIQUID which is stored & filtered in the receiver/filter

dryer.

The EXPANSION VALVE

or ORIFICE TUBE controls the amount of gas allowed into the BLUE low pressure

pipe, this rapid drop in PRESSURE causes the liquid to "boil off"

ie turn back into a gas, in doing so it becomes very cold and when it

passes through the EVAPORATOR on the way back to the compressor it will

absorb any warm/hot air blown through the evaporator by the vehicles heater/air-con

blower.

This system shows an

expansion valve with its capillary sensing tube picking up the temperature

in the blue pipe to open & shut the valve. In Orifice tube systems

there is no actual valve, just the tiny tube metering the liquid like

a carburetor jet. In most systems there will also be a thermostatic control

switch to regulate the desired temperature and pressure switch/s to sense

the low and high pressures that will need the compressor to be stopped.

There will also be a "Tap" or service point on both the low

pressure (blue) and the high pressure (red) sides.

In a normal system

the compressor should "cycle" ie start and stop as and when

system pressure demands

Basic maintence/what to do first!

Every Year or when you get a problem,

before anything else always complete these simple tasks.

Inspect the engine radiator and

the air-con condenser which is usually fitted in front of it, clear away

any debris as well as blowing out both.

Check that the compressor drive

belt is present and tight.

Remove and clean the cab air filter/s

then make access to the evaporator core so that you can see if the fins

require dust & lint removing. (a common problem that stops air flowing

through)

Inspect visually the pipe work to

see if there has been a leak (look for signs of air-con oil carried out

by the escaping gas) and see if the compressor clutch "clicks"

when you turn it on and off (engine stopped, ignition on)

Identification

The first job is to identify what

gas you are using, if your system is mid-late 90's onwards then it should

be safe to say that you are on the later ozone friendly R134a gas.

Before that the standard was R12 gas. Besides a sticker in the engine

bay stating what you have, you will be able 99% of the time to tell by

the two connections used to service the system. (the 1% is if someone

has converted old to new gas without fitting the new connectors as should

be done)

This

is the type of dust cap and connector fitting used on R134a systems. Caps

can be colour coded red & blue or just plain Black and in other styles

to that shown they have a central peg inside with the threads to screw

into the connector. This

is the type of dust cap and connector fitting used on R134a systems. Caps

can be colour coded red & blue or just plain Black and in other styles

to that shown they have a central peg inside with the threads to screw

into the connector.

Also

shown here is the type of connector used to service the system, note the

collar with QRC type connector and the red coloured knob to open the system

connector valve. Note-They use different size connectors to prevent getting

the High and Low pressure service hoses mixed up. Also

shown here is the type of connector used to service the system, note the

collar with QRC type connector and the red coloured knob to open the system

connector valve. Note-They use different size connectors to prevent getting

the High and Low pressure service hoses mixed up.

This

is an elbow adaptor that shows both the male and female fittings traditionally

used a lot in past in the A/C trade. This

is an elbow adaptor that shows both the male and female fittings traditionally

used a lot in past in the A/C trade.

Commonly found on test gauges, hoses,

etc. the male was also used as the service connection on the R12 systems,

it has the schrader valve core visible inside & the male connection

screws over it with a probe to open the valve.

If your system has been converted

to R134a then adaptors should of been fitted to convert the male to the

R134a type above.

What should happen

Start the engine. With

air-con switched off the compressor pulley(s) should be rotating with

the clutch at the front stationary, now switch on the air-con and blower

fan. The clutch should engage, you may hear the click but you should notice

a slight change in engine revs. Set the throttle to a fast idle, now hold

the two pipes connected to the compressor, you should notice that the

smaller one is getting hot and the fat one is getting colder?

Listen in case the

system cycles-ie the clutch releases, what you should get is the air being

blown through the evaporator in the cab becomes cold and with all the

doors shut it will pull the air temperature down to a point where the

thermostat will stop the system as it has reached maximum coldness, or

the amount that you have set it to.

As it warms in the

cab the system senses this and starts up again. The time taken between

cycling on and off will vary depending on how fast you have the blower

set, on high it may run continuously where as on slow it may be off more

than its on! running it on slow will give the coldest air as it has the

maximum time to get chilled right down and it is best to use this to prevent

the evaporator icing up-it needs time to warm to de-ice and running on

fast may ice it up to a point where the air-con stops working, you stop,

investigate, start working again and get a cold shower when the melted

ice pours out of the roof!

What you can do!

Not a lot really without

at least a set of test gauges and a bit of skill in understanding what

they are telling you.

But, something always

worth checking is the condition on the bearing that the compressor pulley

runs on, whip the belt off & spin the pulley to listen for any rumbling,

while you are there get an air line out & blow the dust out of the

pulley centre through the 3 threaded holes in the front of the clutch

and through the gaps around the clutch/pulley.

If you have tested

to see if the clutch engages but find it won't, check to see if you get

power to the feed wire going into the clutch coil near the front of the

compressor, if there is power & now clutch "click" then

measure the clutch air gap, on the common sanden compressor it is usually

between 15-30 thou, if its more it may be too big an air gap for the clutch

coil to pull the clutch plate into drive. The remedy is to remove the

shaft nut & pull the clutch off using the 3x 1/4unc threaded holes,

you will then find small shim washers on the end of the shaft that can

be removed to set the correct gap see

here for sanden PDF service manual Replacement of the pulley bearing

is not difficult and can also be done without degassing.

There is one aid to

seeing what the system is doing, usually in the top of the Filter/dryer,

or in the pipe work on the suction side can be found a sight glass through

which you can observe the pretty bubbles as the system works. A rough

guide is that when the clutch engages the cluster of bubbles that you

can see will rapidly disappear, on most systems you will see the odd one

or two going by and as long as these do not start turning into hoards

of bubbles then things are not too bad!!. If the low side pressure gets

nearer to the zero or vacuum point the bubble rate will increase rapidly,

this is a good indication that there is not enough gas in the system.

In the last few years

there has been the gradual appearance of DIY repair items, such as top-up

cans of gas and system additive kits. These are sometimes worth

a try but quite often unless you have a regular "leaky" system

that you know will be low on gas, it won't be worth the risk. Too much

gas can damage the system and possibly you in the process. So finally

I finish off by adding a few "FF Facts" for you.

R12 is now illegal

to use for maintence, although operating a system with it in is still

allowed.

99.9% of R12 systems

can be converted to R134a, although there will be a reduction in the efficiency

with the new gas.

Venting of a systems

old gas to atmosphere is taboo, wasteful because it can be cleaned for

reuse and there is also the handy benefit of being able to measure how

much gas there is in there when diagnosing difficult faults!

The Filter/dryer-Receiver/accumulator

contains a desiccant to absorb moisture, 3-4 years is a good age for replacing

them, after that you risk the desiccant breaking down & a system flush.

Replacing any major

component of the system will require the adding of refrigerant oil, to

replace oil that would of been inside the old component.

It is good practice

to replace the Filter/dryer-Receiver/accumulator after breaking open the

system for servicing/repairs, the new desiccant in them will enable them

to absorb any moisture that may be in the system even after the usual

30+min period of the system being drawn down into a deep vacuum to extract

moisture(you also need the vacuum to recharge the system)

If you have a compressor

failure, make sure the engineer does a complete system flush to remove

all metal particles. Most compressor manufacturers/suppliers will void

warranty for failing to do it. Flushing the system is the best way to

start afresh, a clean system, fresh oil and recharging with a know quantity

of gas.

As a rule of thumb,

the minimum pressure in the low side wants to be 15psi, it will work way

lower than that if the pressure switch hasn't shut it down, but around

10-15 psi is required to prevent the system creating a vacuum.

A safe goal for max

high pressure is around the 350psi mark. But if you have an old Lady of

a system and she's showing her age, it is often best to keep the amount

of gas in the system as low as possible so that maximum working pressures

are low and within what the ageing hoses will stand. Ever recharged an

old system only to see it burst a hose and loose all that gas!!!

A ball park figure

for enough kit to test, service & repair basic Air-con systems will

set you back a minimum of £1500. (recovery unit, measuring cylinder,

gauges, sniffer, vacuum pump) Double that to be able to start doing

it properly, i/e flushing kit, dye tracer kit, etc!

Useful links.

AMA

Agricultural

& Mobile Airconditioning, Nailsworth, Glos (crap website but a good

company!!)

Robinair US

giant in air con servicing equipment

Sanden

compressors One of the most popular compressor manufacturers

Wigam

Italian service and maintence equipment

Aircondition.com

(forum) Handy US forum

|